#Clamshell Bucket

Explore tagged Tumblr posts

Text

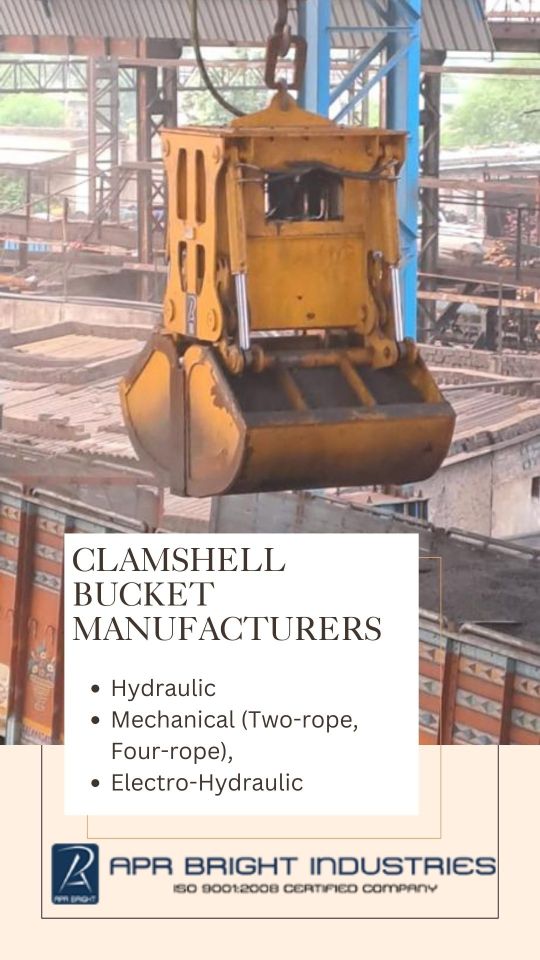

Clamshell Bucket Manufacturers

Clamshell Bucket is used for handling coal/coke, grain, fertilizer, sand, slag, ash, cement, clinker, limestone, iron ore etc. Clamshell Grab Bucket range of 0.5 cbm to 10 cbm capacity and as per requirements. It comes in the from of Hydraulic, Mechanical (Two-rope, Four-rope), and Electro-Hydraulic.

APR Bright Industries is the manufacturers of Clamshell Bucket and delivered clamshell grab buck to industries like Steel, Cement, Coal Mines, Ports, Ship Yard, Fertilizer, Power Plants, Foundries, Construction, Chemical Plants.

Contact APR Bright Industries for more information on clamshell bucket.

#grab bucket#metalrecycling#scraprecycling#materialhandler#scrapbaler#nonferrous#recyclingmachinery#metalscrap#clamshell bucket with loader#clamshell bucket

0 notes

Note

Hello!! As always, I have another request. This one is where Dante and the reader are at the beach. They're having a competition for who can create the best sand castle or sand sculpture, only their beautiful creations to get washed away by the ocean!

An: SORRYY THIS ONE WAS SHORT IM DOING WURK!

Washed away

The beach was alive with warmth, laughter, and the shrieking cries of distant gulls. The tide whispered and kissed the shore with the ease of a lover returning home, while sunlight danced across the ocean’s surface like fireflies on water.

You dropped your bag near a large umbrella, kicking off your sandals and letting your toes sink into the soft, warm sand. “I still can’t believe I let you talk me into this,” you said, giving Dante a skeptical side-eye as he plopped down beside you, already shirtless and smug.

“Come on,” he drawled, running a hand through his silver hair as he dug a plastic spade out of the beach bag like it was Excalibur. “You work too much. Beaches are therapeutic.”

You arched a brow. “Since when does Dante Sparda know anything about therapy?”

“Since right now.” He wiggled his eyebrows. “C’mon. Sun, sand, a stupid contest. What’s not to love?”

“Fine,” you relented with a small laugh, grabbing a bucket. “But if I win, you’re buying dinner and dessert.”

“Deal,” he smirked. “But if I win, I get to see you eat a chili dog with extra onions while wearing a ‘World’s Best Loser’ shirt.”

You groaned. “That’s oddly specific.”

“It’s already in the car.”

A few feet away, Lady had laid out her towel with military precision and was now sunbathing with one arm slung over her eyes, a large cocktail glass resting dangerously close to the sand. Meanwhile, Nero was attempting to build a volleyball net out of driftwood and string, only to be immediately tackled by a rogue crab.

“OH, GOD—IT'S ON ME! GET IT OFF!”

Lady didn’t even flinch. “Be one with nature, Nero.”

Back at your little kingdom of competition, you and Dante had begun your masterworks.

You went for elegance and symmetry—a towering castle with winding staircases made from stacked clamshells, delicate turrets you carved with surprising grace, and even a little moat fed by a small channel you dug from a tide pool.

Dante, of course, went for chaos.

His was… well. It was a sand sculpture of a demonic gladiator with wings, fangs, a ridiculous six-pack, and you were pretty sure it had your name tattooed across the bicep.

You stood back and stared. “Why does it have nipples?”

He squinted proudly at it. “Artistic integrity.”

You snorted. “You just wanted to flex with a sand sculpture.”

“Is it working?”

You rolled your eyes, trying to suppress the heat rising to your cheeks. The glint in his eye when he caught your smile made your heart skip.

As the two of you worked, you found yourself glancing at him more and more. His skin gleamed with sweat and sea salt, silver hair tousled by the breeze. Despite his usual swagger and devil-may-care attitude, there was something boyishly endearing in how seriously he took his silly sculpture. He was competitive, sure—but he was also genuinely enjoying himself.

You smiled to yourself and knelt beside your own castle, placing the final seashell atop one of the turrets. “There,” you whispered. “Perfect.”

“Hey,” Dante said suddenly, softer than usual. When you looked up, he was crouched nearby, watching you.

“Yeah?”

He hesitated. “This’s nice, y’know?”

Your brow furrowed slightly. “What, the sand sculptures?”

“No. Just… you. Us. Doing dumb stuff. No demons. No screaming. No blood.” He rubbed the back of his neck, a little sheepish now. “I don’t get a lot of that. It’s good.”

Your heart fluttered at the rare vulnerability in his voice.

You reached out and brushed a bit of sand off his cheek. “Then let’s do more of this.”

He smiled, slow and lazy, eyes warm like sun-soaked whiskey. “Yeah. Let’s.”

But of course, the ocean had other plans.

A moment later, you heard it—the sudden whoosh of a larger wave cresting. You turned just in time to see it rushing toward shore, white foam surging like a tide-fueled freight train.

“Uh, Dante—”

“Aw, hell—”

CRAAAAAASSSHHH.

The wave rolled in and swept across the shore with an aggressive hiss, devouring both of your works of art with zero remorse. Your castle dissolved in seconds, shells scattering like confetti. Dante’s demon suffered an instant decapitation and lost both arms before collapsing into a lumpy mess.

You sat in stunned silence for a beat, soaked to the thighs, mouth slightly open.

Dante blinked, completely drenched and dripping. “Well.”

“…My castle,” you murmured, “was a symbol of peace and order.”

“And mine,” Dante said solemnly, “was a testament to raw, unfiltered masculinity.”

Both gone. Just like that.

Then you both burst out laughing, unable to stop as the sea mocked you with retreating foam and scattered seaweed.

Behind you, Nero had escaped the crab only to find himself being used as a towel rack by Lady, who had taken his shirt, draped it over her legs, and declared it a “perfect sunshade.”

“I’M STILL WEARING MY SHIRT UNDER THE SAND!” he protested.

She sipped her drink. “You’re welcome.”

Dante leaned back on his elbows in the sand beside you, still chuckling. “Wanna try again?”

You shook your head, wiping tears of laughter. “Nah. The ocean clearly hates art.”

He looked at you sideways, eyes softening again. “Still, I think we made something pretty damn good.”

You raised an eyebrow. “The the ocean demon?”

“No,” he grinned. “This.”

And without hesitation, he leaned in and kissed you, salty and sweet, sun-drenched and soft. You smiled against his lips.

Some things, the ocean couldn’t wash away.

Made by @yo-ri-su-ki, do not copy or translate my work! Reposts and likes appreciated!!

An: Cheesy romance stories my beloved

34 notes

·

View notes

Text

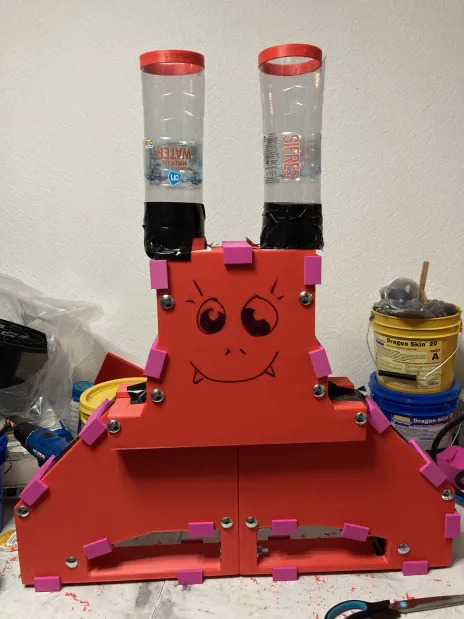

Fin V5 - V7: Utter Failure

I have for the last three or so weeks been sprinting ahead on new designs of fins which reduce the size but increase the thickness to create a stiffer fin.

This entire process has been an utter disaster again and again. My printer has been acting up terribly and it took me eleven days to print three days worth of parts. My parts are still warped and some had terrible stringing. I was also having an extremely difficult time with my CNC to make it behave and I still have not gotten a good pathing software yet set up.

I still did try to cast a fin, there were some noticable gaps but I hoped I could seal them. Getting the cast set up was four hours because I had to keep drilling out holes because nothing would align and nor would the poorly sized bolts actually fit. I had hoped I could use the bolts as alignment pins though in hindsight that was a fool's errand and the availability of specialty bolts seems fairly obscure in NL, and even DE or UK suppliers were not much better. The nice thing is the bolts did create a strong seal where they were positioned to be able to, the downside is that could really only happen because the two halves of the clamshell and not between the parts themselves as my printer and CNC can only make so large of parts.

Still I did forge ahead with the cast, which honestly I probably should have not with how many difficulties I had so far had. The process is messy, and disorganised, but still the casting part itself did not take long. I added two hopper tubes into the mould so I could store more silicone in it and these actually worked really well. Unfortunately the cast did not go well. It eventually started leaking and it did not fully fill. I did try adding more but after adding an extra 600mL on top of the early 900mL extra which represents around a 33% additional wastage I called it.

(I drew a face on it because it needed a face)

Unfortunately the next day the leaking was very bad, and despite my best efforts I was entirely unable to even remove the bolts to separate the clamshell and see even vaguely what it looks or feels like.

I think what I need to do is take a few weeks and really refine my process. I need to make it so my moulds are water tight so they do not leak. I also need to make it so I do not get silicone everywhere nor have to use nearly as many paper towels or clean nearly as many buckets.

I have a few ideas how to achieve this, but all of these will take some time to sort out. I am certainly not giving up, and though these setbacks are frustrating, I am feeling still plenty motivated to move forward.

Tuesday I will begin again with renewed plan and vigor. Doeg!

33 notes

·

View notes

Note

Grabber from bob the builder, hes just a silly british excavator in which i want to kiss his flat face💚💚💚💚

“A crawler excavator with a dozer blade on his front as well as a clamshell bucket”

Part of a pair of caterpillar track machines with Gripper

Reminder, the premise is “would a normie think it’s weird to find them attractive?” (Would they have to “hear me out?”)

#reblog for a bigger sample size#Bob the builder grabber#gripper and grabber#bob the builder#hearmeoutworthypoll#hear me out#unconventionally attractive#down bad#why he kinda#poll#polls#tumblr polls

10 notes

·

View notes

Text

Calling A Wolf A Wolf Sentence Starters Part Three

Starters from Calling A Wolf A Wolf by Kaveh Akbar. Feel free to change pronouns as necessary, and remember to specify muse for multimuse blogs.

CW: Animal injury mention, religious themes, alcohol use, animal death mention, horse breaking mention, food

—

"You just don't know yet which parts of yourself to value."

"Even the trap-caught fox knew enough to chew away its leg."

"Nature rewards this kind of courage."

"The lesson: It's never too late to become a new thing."

"Rip the fur from your face and dive dimplefirst into the strange."

"Some people don't even want to drink."

"This seems a selfishness."

"God loves the hungry more than the full."

"Faith is a story about people totally unlike you building concrete walls around their beds."

"Behind each of their faces? A slowly dying animal."

"Do you feel summoned?"

"Do you feel Heaven closing itself to you like a clamshell snapping shut?"

"Blessed are those who can distract themselves."

"Blessed are the distractions."

"As a child, I wasn't so much foreign as I was very small."

"Learning the names of things?"

"Each new title a tiny seizure of joy!"

"I polished them like trophies."

"Even our great-grandparents saw different blues."

"Now, I resist acknowledging the riches I've inherited."

"It's so much easier to catalog hunger, to atomize absence, and carry each bit like ants taking home a meal."

"I am insatiable."

"Every grievance levied against me amounts to ingratitude."

"I need to be broken like an unruly mustang."

"Their mouths were zeroes, little pleasure portals."

"Today, words fly in all directions."

"I don't know how anyone does anything."

"I miss my mouth sipping coffee."

"Spend the day explaining the dribble to strangers?"

"I am not a slow learner."

"I am a quick forgetter."

"Such erasing makes one voracious."

"If you teach me something beautiful, I will name it quickly before it floats away."

"My father moved patiently."

"Occasionally, they'd glance over at my clumsy mirroring."

"Smile a little?"

"They looked like a photograph of a famous ghost."

"I ached to be so beautiful."

"I hardly knew anything yet."

"I knew only that I wanted to be like them."

"Years later, I am still picking romas out of my salads."

"With drinking, however, I've always been prodigious."

"I've always been prodigious."

"A garden bucket filled with cream would disappear!"

"I swear, I could conjure rain clouds from piles of ash."

"So, trust me now!"

"When I say thirst, I mean defeated."

"Imagine being the sand forced to watch silt dance in the Nile."

"Today, I'm finding problems in areas where I didn't have areas before."

"I'm grateful to be trusted with any of it."

"It just seems such a severe sort of miraculousness."

"This can guide us forward or not guide us at all."

"Maybe it's that forward seems too chronological."

"The future-perfect always sounds so cavalier."

"Someday this will all have been worth it."

#roleplay memes#rp memes#writing prompts#rp starters#roleplay starters#sentence starters#dialogue starters#dialogue prompts#book rp starters#literature rp starters#poetry sentence starters#poetry rp memes#writing rp meme#poetry roleplay memes#literature rp memes#literature roleplay memes#book roleplay memes#sentence memes#sentence rp meme#sentence rp memes#sentence roleplay memes

11 notes

·

View notes

Text

Repo Man – Chevy Malibu

Alex Cox’s Repo Man is one weird, satirical ‘80s classic. That it centers on car repossession (in addition to government conspiracies, rampant criminality, and radioactive alien corpses) makes it a car movie, of sorts. A lot of cars get broken into, stolen, and repossessed over the course of the film, but the most important car plot-wise is a beige Chevy Malibu driven by a sweaty, one-eyed mad scientist. What makes this Malibu one of the worst cars in movie history? For one, it is super hot inside even with the windows down and AC cranked up. And two, the decaying alien corpses in the trunk are so radioactive that anyone unfortunate enough to open the back end is instantly fried to powder, leaving nothing but a pair of smoldering shoes to tell the tale. For the final scene, the car was painted in 3M reflective paint (at $600 a can!) and hit with spotlights to give it that ghostly glow.

Maximum Overdrive – Happy Toyz Semi

It turns out Emilo Esteves has a knack for appearing in bad car movies as he followed up Repo Man by starring in Stephen King’s Maximum Overdrive. Tired of Hollywood directors butchering his ideas, King directed the movie himself (his first and last attempt at directing). Maximum Overdrive kicks off a consistent theme on this list: killer cars. The premise is hokey and never actually scary (seriously, 1974’s Killdozer is about a killer bulldozer that stalks its victims at 5 mph). In the case of Maximum Overdrive, it isn’t just cars, but all mechanical objects become possessed and homicidal, including one very grumpy toaster. A marauding group of killer semis is led by a Happy Toyz truck with a big fiberglass Green Goblin face on the radiator. Why Marvel’s Green Goblin? We’d ask Stephen King, but the author says he was drinking too much at the time to remember much of anything about the filming.

The Car – Lincoln Continental Mk III

Within the genre of killer cars, The Car ranks … among them. This low budget 1977 horror flick stars James Brolin as Deputy Wade Parent and a very dower looking 1971 Lincoln Continental Mk III. The car of The Car (inventive title, no?) is barely recognizable as a Lincoln thanks to extensive custom work by George Barris, famed customizer of the Hirohata Merc and the 1960s TV Batmobile. Barris added a high belt line, blacked out windows to match a black paint job, massive fenders, and a lowered roof line that gives the car a menacing glower. But rather than scary, the car of The Car ends up looking as corny as the movie’s dialogue, earning it a spot on our list.

Jeepers Creepers – Chevy COE

Far scarier than a possessed car is a car driven by a people-eating demon as seen in Jeepers Creepers. The grim rust bucket in question is a 1941 Chevy cab-over-engine (COE) with a blaring horn and a gnarly cowcatcher used to ram unsuspecting motorists off the road. This being the horror genre, there’s a little bit of tongue-in-cheek humor with the addition of a vanity license plate that reads BEATNU. The Creeper’s Chevy COE is simultaneously one of the best scary movies cars of all time and one of the worst cars to see in your review mirror.

Corvette Summer – C3 Corvette

In between iconic performances in Star Wars and The Empire Strikes Back Mark Hamill starred in a little movie called Corvette Summer. The “adventure comedy,” as it was billed, follows a California teenager as he travels to Las Vegas in search of his stolen customized Corvette. Like many custom cars, the Corvette in question has clearly been an ambitious labor of love that got wildly out of control. The elaborate customization included a fiberglass nose shell, candy red paint with flame decals, side pipe exhaust, and a custom rear end with a large Chevy bowtie logo brake light. The car’s custom clamshell hood arrived before the feature debuted on the next-generation (fourth) Corvette. The car was also swapped from left hand to right hand drive to make it easier for the ladies’ man Hamill to chat up girls on the sidewalk while cruising. It boggles the mind how anyone could get a date driving this Hot Wheels-in-real-life monstrosity, but hey, the ‘70s were a weird time.

Dumb and Dumber – Mutts Cutts Van

In Dumb and Dumber, Harry (Jeff Daniels) and Lloyd (Jim Carey) travel from Rhode Island to Aspen, Colorado to deliver a “lost” briefcase. A good many of the miles are covered in Harry’s Ford Ecoline panel van customized for his work as a dog groomer. Like all committed dog groomers, Harry fitted his car with end-to-end shag carpeting, a nose, mouth (with tongue), ears, legs, and a tail. And that isn’t even the extent of the Mutts Cutts van, it also includes free samples of the most annoying sound in the world, plenty bottles of warm “beer,” and $200 car alarm. The duo ends up out of gas and desperate enough to trade the van for a minibike aka the perfect mode of transport for high-elevation mountain travel. What makes this one of the worst movie cars of all time? Just image the smell once you take it through the car wash…

17 notes

·

View notes

Text

Lake Dredge Explained Benefits,Methods and Environmental Impact

Lake dredging is a vital process that removes accumulated sediment, organic debris and pollutants from the bottom of lakes to restore water depth,improve water quality and enhance aquatic ecosystems.Over time lakes naturally fill with silt and nutrients,leading to shallow, murky waters and reduced biodiversity.Dredging helps reverse these effects, making lakes safer, cleaner, and more navigable.This blog explores the key benefits of lake dredging, the various methods used from mechanical to hydraulic and the environmental considerations involved. Understanding the full scope of lake dredging allows communities to make informed decisions for long-term lake health and sustainability.

Why Lakes Need Dredging The Problem of Sediment Buildup?

Over time,lake dredge accumulate sediment from natural runoff,decaying vegetation and human activity.This gradual buildup reduces water depth,limits recreational access and creates an ideal environment for invasive plants and algae blooms.As sediment thickens,oxygen levels decline, leading to poor water quality and dying aquatic life.In some cases the lake may become unsuitable for boating, fishing, or swimming. Dredging restores depth and circulation, removes harmful material, and rejuvenates the lake’s overall health.Without it, lakes can become stagnant,overgrown and unusable making regular dredging a critical step in preserving these vital freshwater resources.

Key Benefits of Lake Dredging

Lake dredging offers a wide range of benefits beyond just aesthetics. It improves water quality by removing contaminated sediment and excess nutrients like phosphorus and nitrogen that fuel algae growth. Restored depth enhances recreational use, allowing boats and anglers better access. It also increases water storage capacity, crucial for stormwater management and flood control. Additionally, dredging revitalizes aquatic habitats, encouraging the return of fish and native plant life. For property owners, dredging can significantly boost shoreline value and safety. These combined benefits make lake dredging an essential investment for communities committed to environmental restoration and sustainable water management.

Common Dredging Methods Used in Lakes

Several dredging methods are used depending on the lake’s size,sediment type and environmental sensitivity.Mechanical dredging involves excavators or clamshell buckets removing sediment directly from the lakebed ideal for shallow,small lakes.Hydraulic dredging uses pumps to vacuum slurry (a mix of water and sediment) through pipes to a containment site, offering efficient removal with minimal surface disruption. Cutterhead dredges, auger dredges, and suction dredges are also popular for precision and adaptability. Choosing the right method is crucial to the success of a project and must consider sediment volume, access points, disposal plans, and ecosystem impact.

Environmental Considerations in Lake Dredging

While lake dredging improves water quality and depth, it must be carefully managed to avoid environmental harm. Disrupting the lakebed can release trapped toxins or disturb fish spawning habitats. That’s why environmental assessments and sediment testing are essential before any dredging begins. Modern dredging practices aim to minimize impact through careful planning, timing, and sediment containment. Often, dredging is scheduled outside of breeding seasons, and silt curtains are used to prevent turbidity from spreading. When done responsibly, dredging not only avoids ecological damage but also enhances biodiversity by restoring a healthier aquatic environment for native species.

Dredged Material Disposal and Reuse Options

After dredging, handling the removed sediment often called spoils is a key part of the project. Depending on its composition, dredged material can be disposed of in confined disposal facilities, used for land reclamation, or even repurposed as topsoil or fill material. In some environmentally friendly approaches, clean sediment is used to restore wetlands or rebuild eroded shorelines. However, contaminated material may require specialized treatment or containment. Proper disposal ensures that toxins aren’t reintroduced into the ecosystem. Innovative reuse strategies are transforming dredged sediment from waste into a valuable resource, adding sustainability to the dredging process.

The Role of Dredging in Algae and Weed Control

One of the most visible problems in poorly maintained lakes is the overgrowth of algae and aquatic weeds, driven by nutrient-rich sediment. Dredging addresses this by removing the nutrient-laden sludge that fuels such outbreaks. By reducing internal nutrient loading, dredging limits algae blooms and invasive plant spread without relying on chemical treatments. It also increases light penetration and water movement, both of which help restore the lake’s natural balance. This makes dredging a long-term, sustainable solution for lake management, especially in areas where repeated herbicide use or manual weed removal has proven ineffective or damaging.

Planning a Lake Dredging Project What Communities Should Know?

Dredging a lake is a complex undertaking that requires coordination, permits, environmental assessments, and community involvement. Before starting, a bathymetric survey is typically conducted to map sediment levels. Project goals must be clearly defined whether for recreation, flood control, or habitat restoration. Budgeting and funding are critical, as dredging can be costly. Regulatory compliance with local and federal environmental agencies is also necessary.Engaging stakeholders early and educating the public about the project’s benefits can ease concerns and build support. With careful planning, a dredging project can restore a lake’s health and utility for generations to come.

Conclusion

Lake dredging is a powerful tool for restoring and preserving the health,functionality and beauty of freshwater ecosystems.By removing built-up sediment and pollutants, dredging improves water quality, supports aquatic life and enhances recreational access. With a variety of methods available, communities can choose solutions tailored to their environmental and logistical needs.While the process requires thoughtful planning and environmental care, the long-term benefits far outweigh the challenges.From preventing algae blooms to boosting property values,lake dredging plays a vital role in sustainable water management.When done responsibly,it ensures that lakes remain vibrant,clean and usable for future generations.

0 notes

Text

Buy Wheel Excavator in India – Compare Prices, Features & Best Deals 2025

A wheel excavator (also known as a wheeled excavator or wheel Poclain) is a highly efficient earthmoving machine designed for projects where mobility and speed are essential. Unlike tracked excavators, which are suited for off-road and rough terrain, wheel excavators are mounted on durable rubber tires, allowing them to travel easily on paved roads without causing damage. This makes them an ideal choice for urban infrastructure, road construction, utility work, and municipal maintenance tasks.

Wheel excavators typically offer operating weights ranging from 10 tons to over 20 tons, with digging depths and reach comparable to tracked machines. One of the key advantages of a wheel excavator is its ability to move between job sites without needing a trailer — reducing setup time and lowering operating costs. The machine’s powerful hydraulics, 360-degree swing, and compatibility with a wide range of attachments (such as breakers, grapples, and clamshell buckets) make it a flexible tool for a variety of applications.If you are planning to buy a wheel excavator in India, selecting the right model depends on factors such as required digging depth, lifting capacity, and ground conditions. Available with options like two-piece booms, offset booms, and dozer blades, these machines provide an efficient, cost-effective, and reliable solution for modern job sites that demand productivity with mobility.

0 notes

Text

Mechanical Dredges Remove

Mechanical dredges remove material by scooping it from the bottom and then placing it onto a waiting barge or into a disposal area. Dipper dredges and clamshell dredges, named for the scooping buckets they employ, are the two most common types. Mechanical dredges are rugged and can work in tightly confined areas - mechanical dredging.

0 notes

Text

Breezly Bruin headcannon

After quite the day of clam digging along the shores of Safety Sound and Norton Sound near Nome, our favourite polar bear gets his clam harvest rinsed off in a bucket of salt water (to remove sand and grit from inside the clamshell) with an eye towards clam chowder--howbeit more than likely using evaporated milk considering the cost of transporting fresh milk in Alaska's High North.

No doubt impressing even his girlfriend, Betty Bruin--and her girlfriends as well as came over for the repast, complete with Sailor Boy pilot crackers.

#hanna barbera#headcannons#fanfic ideas#breezly bruin#nome#clam digging#clam chowder#hannabarberaforever

0 notes

Text

Unlock the Full Potential of Your Tractor with a Root Grapple

If you're dealing with heavy brush, roots, or storm debris, a root grapple for tractor can make your job significantly easier. Unlike standard buckets, root grapples are designed with tines and a clamshell-style grip that allows you to lift and carry irregular, bulky materials without scooping up unnecessary dirt. This not only improves efficiency but also reduces wear and tear on your tractor and saves you time during cleanup or land clearing projects.

One of the biggest advantages of using a root grapple for tractor is its versatility. Whether you're a landowner maintaining wooded acreage, a contractor preparing a construction site, or a farmer clearing old fencing and tree stumps, this attachment can handle it all. The strong hydraulic arms give you precise control, making it easy to move brush piles, dig up embedded roots, or stack logs neatly—tasks that would otherwise require multiple tools or hours of manual labor.

When investing in a root grapple for tractor, it's important to choose one that matches your machine's size and workload. Compact grapples are great for sub-compact tractors, while heavy-duty versions are built for larger machines handling bigger jobs. Look for features like reinforced steel tines, greaseable pivot points, and protected hydraulic lines to ensure long-lasting performance. With the right grapple in place, your tractor becomes a more powerful, productive, and efficient tool for any outdoor task.

Explore more insights on this topic in our blog - https://medium.com/@qickattach/unlock-the-full-potential-of-your-tractor-with-a-root-grapple-022ccbca4792

0 notes

Text

Mechanical Clamshell Grab Bucket

Mechanical Clamshell Grab Bucket comes in the form of two rope, and four rope grabs bucket designed to handle ore grab, coal grab, grain grab, wood grab, sand, gravel, coal, cement, dry or wet bulk material etc.

Clamshell Bucket wear resistant steels and capable to work with open or closed shells depend upon the material. Our custom grab bucket not only increase the productivity but enhance the performance of crane also.

APR Bright Industries is known for grab bucket manufacturers in India and delivered customized clamshell bucket to many respective industries includes port, ship crane, steel plant, cargo, agriculture, construction etc.

Contact us today and let us inspect your industry.

0 notes

Text

The Significance of Precision Engineering in Industrial Machinery

Precision engineering is a critical component in industrial machinery, directly influencing efficiency, reliability, and longevity. In industries where accuracy, durability, and safety are paramount, investing in high-quality, precision-engineered machinery can significantly impact operational success. LeisterTech is a leader in precision engineering, offering solutions that optimize industrial performance while ensuring long-term durability and safety.

In this article, we explore the role of precision engineering in industrial machinery and how LeisterTech’s commitment to accuracy enhances equipment performance.

Understanding Precision Engineering

Precision engineering focuses on designing and manufacturing machinery with exact specifications and tight tolerances. By minimizing variations in machine components, precision engineering enhances performance and reliability, particularly in high-pressure industrial environments where even the smallest misalignment can lead to operational inefficiencies.

Why Precision Engineering Matters in Industrial Machinery

Industrial equipment must endure rigorous conditions while delivering consistent results. Here’s why precision engineering is essential:

Superior Performance: Precision-engineered machinery operates smoothly with minimal friction, reducing wear and tear while improving efficiency.

Enhanced Reliability & Safety: High-precision components lower the risk of malfunctions, ensuring safer operations in heavy industries.

Extended Equipment Lifespan: Precision-machined parts experience less deterioration, reducing the frequency of replacements and optimizing return on investment.

Lower Maintenance Costs: With fewer breakdowns, businesses can save on repairs and minimize downtime, improving overall productivity.

LeisterTech’s Dedication to Precision Engineering

At LeisterTech, precision engineering is at the core of every product. From billet lifting magnets to hydraulic pushers, every component is meticulously crafted to meet industry-leading standards. Here’s how LeisterTech maintains precision in its manufacturing:

Advanced Manufacturing Techniques

LeisterTech utilizes state-of-the-art technology to ensure precise component fabrication, optimizing compatibility and efficiency.

Rigorous Quality Control

Every product undergoes extensive quality testing to meet both industry regulations and LeisterTech’s internal precision benchmarks.

Tailored Solutions for Industrial Needs

LeisterTech specializes in custom-built machinery, ensuring that each product is designed for seamless integration within specific industrial applications.

Highly Skilled Engineering Team

LeisterTech’s expert engineers design products to withstand the demanding conditions of heavy industries, ensuring reliability and longevity.

Precision Engineering in LeisterTech Products

1. Hydraulic Pushers

Hydraulic pushers require precision engineering to deliver controlled force and seamless material handling. LeisterTech’s hydraulic pushers ensure:

Consistent force application

Reduced risk of material damage

Enhanced operational safety

2. Billet & Bundle Lifting Magnets

Lifting magnets play a crucial role in heavy material handling, and LeisterTech’s precision-engineered magnets provide:

Secure grip strength

Minimized risk of load slipping

Increased workplace safety and efficiency

Learn more about LeisterTech’s billet lifting magnets and their applications.

3. Grab Buckets

LeisterTech’s precision-engineered grab buckets, including clamshell and log grab varieties, deliver:

Precise material handling

Enhanced durability and longevity

Reduced wear and tear on components

How Precision Engineering Increases Equipment Longevity

Precision engineering significantly impacts equipment lifespan by minimizing component stress and wear. Here’s how:

Fewer Component Failures: Precision manufacturing ensures seamless part integration, reducing mechanical stress.

Longer Service Intervals: High-precision components wear out slower, extending maintenance cycles.

Optimized Resource Utilization: Durable machinery lowers repair and replacement costs, promoting cost savings.

Explore how LeisterTech’s engineered solutions optimize industrial performance.

The Impact of Precision Engineering on Operational Efficiency

Precision engineering directly contributes to operational efficiency in industrial settings:

Reduced Downtime: High-quality components minimize unexpected breakdowns.

Streamlined Processes: Machinery functions seamlessly, improving workflow and productivity.

Better Resource Allocation: Companies can focus resources on production rather than frequent repairs.

Frequently Asked Questions About Precision Engineering

1. What is precision engineering?

Precision engineering involves manufacturing machinery with exact specifications to ensure optimal performance and reliability.

2. How does precision engineering improve equipment reliability?

By minimizing wear and misalignment, precision engineering reduces malfunctions and enhances operational consistency.

3. Why is precision important in hydraulic pushers?

Precision ensures controlled force application, improving material handling and safety.

4. How does LeisterTech maintain high precision standards?

LeisterTech employs advanced manufacturing technologies, rigorous quality control, and expert engineering teams.

5. Does precision engineering reduce maintenance costs?

Yes, by ensuring components experience less wear, it minimizes the need for frequent maintenance and repairs.

6. What industries benefit from precision-engineered machinery?

Steel manufacturing, construction, and mining are just a few industries that rely on precision-engineered equipment.

7. How does precision engineering impact workplace safety?

Precision engineering enhances safety by reducing the risk of malfunctions and equipment failures.

8. How does LeisterTech test its precision-engineered products?

LeisterTech conducts rigorous quality checks to ensure compliance with industry standards and customer requirements.

9. Can precision engineering be applied to custom machinery?

Yes, precision engineering is essential for customized solutions, ensuring optimal functionality for specific applications.

10. How does precision engineering boost productivity?

By minimizing downtime and ensuring smooth operations, precision-engineered machinery helps businesses maintain consistent production rates.

Conclusion: Investing in Precision Engineering for Industrial Success

Precision engineering is not just a technical benefit—it is a fundamental aspect of industrial efficiency and reliability. LeisterTech’s dedication to precision ensures that every product delivers superior performance, safety, and longevity. By investing in precision-engineered solutions, companies can optimize productivity, reduce operational costs, and enhance workplace safety.

Explore LeisterTech’s full range of precision-engineered solutions and experience the advantages of high-quality industrial machinery.

0 notes

Text

Sole source of heat!

(That, however, is a CERAMIC fireplace, which means it's going to absorb quite a lot of heat and slowly re-radiate it back into the room over time. Absolutely the latest and greatest thing coming out of the Nordic countries. The Royals of Sweden have them in ALL of their palace rooms! *ttiters behind fan*)

In the early 1800s, there was zero chance of having any other source of heat, unless you were in Japan and lived at an onsen, or in Korea and had an ondol under your house. You could literally have a brazier (metal pan with hot coals), a fireplace (several designs were attempted to improve both the draft to keep smoke out of the room and to reflect and retain heat rather than letting it escape up the chimney), oil lamps, rushlights, or candles (tallow and beeswax, if you could afford the latter). These were the items that could provide heat to a room over time.

"Bed Warmers" were basically clamshell style devices that you put hot coals into, and then slid them around inside the bedding, between the sheets, to warm them up just before climbing inside to sleep. This had to be done carefully to keep from smoking and staining or singeing the sheets, and obviously you couldn't keep them there. They weren't meant to heat an entire room, however.

Hot water bottles were made out of ceramic, glass, some even out of metal...but you had to be rich to afford one, and you had to be confident it wouldn't leak, but you could at least keep it in the bed with you. (Metal ones would be wrapped in cloth to keep from searing the sleeper.) Hot baths technically were a thing, but you had to laboriously heat and lug several kettles of water from kitchen to tub--assuming you had the tub, often little more than a half-barrel or oversized bucket--and it wasn't really a soaking experience. (Plus you had to laboriously empty it out again.) But again, both not a room-heating item. (Though the bath does it a little better than you'd think.)

However, those are individual person-warming devices...and while candles and oil lamps are technically a source of flame, they're too small. Braziers were too smoky (and seen as too primitive by the 1800s), so fireplaces of various designs were the only option for heating an entire room in winter, in Europe. (The secret to the ancient Roman hypocaust had long since been lost.)

Also, one more thing: the creation of canines bred to be literal lap dogs, and of course contented cats, which were encouraged to sleep on your lap or on your feet, sharing their body-warmth. But again, that was a single person warming "device" and not something meant to heat an entire room.

Fireplaces (of various designs) were pretty much it.

6K notes

·

View notes

Text

Top Equipment Used in Modern Lake Dredge Projects

Modern lake dredge projects rely on advanced equipment to efficiently remove sediment, restore water quality, and enhance aquatic habitats. Key tools include cutter suction dredgers, which use rotating blades to loosen sediment while simultaneously pumping it away. Hydraulic dredgers are ideal for precision work, offering minimal environmental disruption. For larger projects, clamshell dredges utilize bucket systems to remove significant volumes of sediment. Amphibious excavators provide versatility, operating in shallow or deeper waters. High-tech options like remote-controlled dredgers improve safety and precision, especially in challenging conditions. Support equipment, such as dewatering systems and sediment transport pipelines, streamlines the sediment management process. Together, these tools ensure modern dredging is faster, more effective, and environmentally conscious.

What Is Lake Dredge and Why Is It Necessary?

Lake dredge involves the removal of sediment, debris, and pollutants that accumulate at the bottom of a lake over time. These deposits can reduce water depth, degrade water quality, and harm aquatic life. Dredging restores the lake’s depth and ecological balance, making it crucial for maintaining both recreational and environmental health.

Top Benefits of Lake Dredge for Communities

Dredging a lake enhances water clarity, prevents flooding by improving water flow, and supports recreational activities like fishing and boating. For nearby communities, dredging reduces algae growth, eliminates unpleasant odors, and boosts property values by restoring the lake’s aesthetic appeal.

Common Signs Your Lake Needs Dredge

Key indicators that a lake requires dredging include excessive sediment buildup, murky water, recurring algae blooms, and reduced aquatic biodiversity. Additionally, shallow areas that were once navigable can signal a need for dredging to restore depth and functionality.

The Equipment Used in Modern Lake Dredging Projects

Advanced tools like cutter suction dredgers, hydraulic dredgers, and amphibious excavators play vital roles in modern dredging projects. These machines efficiently remove sediment with minimal environmental impact. Supporting equipment like dewatering systems ensures proper handling and disposal of dredged material.

How Lake Dredging Supports Biodiversity?

By removing accumulated organic matter and restoring natural depth, dredging promotes the return of native plants and aquatic life. This process revitalizes habitats, enabling fish, amphibians, and waterfowl to thrive. Healthy biodiversity benefits the entire ecosystem and fosters a sustainable environment.

Challenges and Environmental Considerations in Lake Dredging

Dredging must be conducted carefully to avoid disturbing wildlife or releasing trapped pollutants into the water. Eco-friendly techniques, such as hydraulic dredging and sediment containment systems, mitigate these risks and ensure the process supports long-term environmental health.

The Economic Impact of Lake Dredge Projects

Restored lakes attract tourism, increase property values, and reduce maintenance costs for water systems. The improved water quality and usability also benefit industries relying on the lake, such as fishing, hospitality, and real estate, contributing significantly to local economies.

Conclusion

Lake dredge is a vital tool for restoring and maintaining the health of aquatic ecosystems. From improving water quality to boosting biodiversity and supporting local economies, its benefits are far-reaching. With modern equipment and eco-friendly practices, dredging ensures sustainable solutions for the challenges facing lakes today. Investing in lake dredging is an investment in environmental preservation and community well-being.

0 notes

Text

Cost-Effective Solutions for WWTP Dredge Operations

Managing Wastewater Treatment Plant (WWTP) dredging operations can be challenging and costly, but innovative solutions are making the process more efficient. Cost-effective dredging methods focus on minimizing downtime, reducing labor requirements, and optimizing resource usage. Technologies like portable dredging equipment, automated systems, and geotextile dewatering bags ensure efficient sludge removal while lowering operational expenses. Additionally, adopting real-time monitoring systems helps identify problem areas and improve planning, reducing unnecessary costs. Sustainable practices, such as repurposing dredged materials or partnering with waste-to-energy programs, further enhance cost-efficiency. By combining strategic planning, modern tools, and sustainable approaches, WWTP dredge operators can achieve effective sludge management while adhering to budget constraints and environmental regulations.

Understanding WWTP Dredging: A Vital Component of Wastewater Management

Dredging in Wastewater Treatment Plants (WWTP) involves removing accumulated sludge, sediments, and debris from settling tanks, lagoons, or clarifiers. This process is essential to maintaining optimal efficiency, ensuring compliance with environmental regulations, and preventing blockages that can disrupt plant operations. Effective WWTP dredging enhances water flow, improves sludge processing, and minimizes the risk of overflows.

Key Equipment Used for WWTP Dredging Operations

Successful WWTP dredge relies on specialized equipment designed to handle varying sludge densities and depths. Common tools include hydraulic dredges, which use suction to remove sludge, and mechanical dredges like clamshell buckets or excavators. Innovative technologies, such as remote-controlled dredges and floating platforms, allow operators to perform precise dredging in hard-to-reach areas, ensuring efficiency and safety.

The Role of WWTP dredge in Sludge Management

Dredging plays a crucial role in the management of wastewater sludge by removing settled solids from lagoons or tanks for further processing. The removed material is typically dewatered, treated, and either disposed of or repurposed for agricultural or energy production uses. This critical step ensures that treatment plants maintain sufficient capacity to process incoming wastewater without disruptions.

Environmental Benefits of Regular WWTP Dredging

Regular dredging of WWTPs helps protect the environment by preventing harmful pollutants and excess nutrients from accumulating and potentially leaching into nearby water bodies. Accumulated sludge, if left unmanaged, can lead to poor water quality, ecosystem damage, and violations of environmental regulations. By routinely dredging, wastewater facilities can minimize their ecological footprint while maintaining compliance with local environmental standards.

Challenges and Solutions in WWTP Dredging Projects

WWTP dredge often presents challenges, such as managing difficult-to-access areas, handling hazardous waste, and minimizing downtime during operations. Modern solutions, such as GPS-guided dredging systems and innovative sludge processing technologies, can overcome these challenges. Additionally, partnering with experienced dredging contractors ensures a streamlined process and mitigates risks during complex operations.

Cost-Effective Strategies for WWTP Dredging

Dredging can be a costly process, but careful planning and the use of advanced technologies can significantly reduce expenses. Preventative maintenance schedules, regular sludge monitoring, and investments in durable equipment help minimize costs over time. Many wastewater facilities also explore the reuse of dredged materials, such as biosolids for agriculture, to offset operational expenses and create sustainable practices.

Case Studies: Successful WWTP Dredging Projects

Numerous WWTPs have benefited from implementing effective dredging programs. For example, a facility with recurring overflow issues resolved its challenges by introducing a hydraulic dredging system, doubling its lagoon capacity and improving treatment efficiency. Another plant adopted remote-controlled dredging to clean a clarifier without halting operations, saving time and money while maintaining compliance.

Conclusion

WWTP dredge is a critical practice for maintaining the efficiency, safety, and environmental compliance of wastewater treatment facilities. By leveraging the right equipment, innovative techniques, and sustainable strategies, plants can effectively manage sludge while minimizing operational disruptions. As technologies continue to advance, WWTP dredging will become even more efficient, cost-effective, and environmentally friendly, supporting the essential goal of safeguarding public health and the environment.

0 notes